SeaBird for oil services

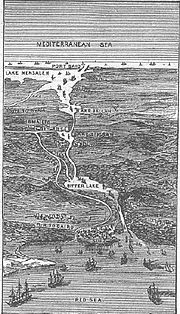

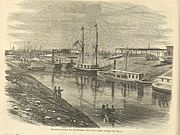

SeaBird for oil services working in the field of marine and diving services in the middle east , and in salvage , survey , anitpollution , and all other services related to oil industry. , Port El Tor , El Tor , Tor , El-Tor Prot , EL YAM , Red Sea , Egyptian Port , SeaBird COMPANY , largest offshore marine service fleet in Middle East , Middle East , Sinai Anchor handling , Tug Supply vessels , Marine Construction , Fire Fighting , Antipollution ....... SeaBird was founded in 1978 with the aim of meeting Egypt's requirements of MARINE AND OFFSHORE services with the Egyptian Calibers, the thing that was lacking in the Egyptian market. Since then, the range of the most integrated, prompt package of MARINE AND OFFSHORE services offered by SeaBird, has steadily increased to become one of the most sophisticated range a competitor can afford. Thus, SeaBird, has chosen to invest heavily in new specializes in Marine Offshore Work such as Marine activities, Diving Activities, Salvage, Offshore Oil Fields Maintenance & Repair Projects, Owns & Maintains Onshore Support Bases. SeaBird owns & maintains a Support Fleet. New Page 1 Welcome Marine Diving Survey Salvage Projects Fleet BASES Operation Port EL TOR SeaBird was founded in 1978 with the aim of meeting Egypt's requirements of MARINE AND OFFSHORE services with the Egyptian Calibers, the thing that was lacking in the Egyptian market. Since then, the range of the most integrated, prompt package of MARINE AND OFFSHORE services offered by SeaBird, has steadily increased to become one of the most sophisticated range a competitor can afford. Thus, SeaBird, has chosen to invest heavily in new specializes in Marine Offshore Work such as Marine activities, Diving Activities, Salvage, Offshore Oil Fields Maintenance & Repair Projects, Owns & Maintains Onshore Support Bases. SeaBird owns & maintains a Support Fleet. SeaBird is now based in Egypt, having started its activities in 1978. It is well capitalized, with fixed assets close to U.S.D. 60 Million. It has a high reputation among the numerous oil companies that used its services for the past fourteen years. SeaBird's fleet of 29 vessels has a wide range of special ships able to perform any exploration and production related support. The fleet includes Anchor Handling Tug Supply Vessels, Tug/Mooring Vessels, Survey Ships, Crane/Flat Top Barges, Firefighting Vessels, Vessels fitted with oil pollution control systems and pollution monitoring. SeaBird's diving activities are extensive, with over 6,000 dives per year. For example Non destructive tests, Magnetic particle inspections, Jackup rigs bottom survey, Coring & piling, Pipelines inspections, Cathodic protection system survey, Diving support for jetty construction works, Submarine cables laying, etc. SeaBird's clients' list includes PHILIPS, AGIP, AMOCO, BP, SHELL, SANTA FE, TOTAL, FUJIKURA, SAIPEM, K.O.C, GASCO, TEXACO, FERTIL, ADMA-OPCO, VMGL,---etc. SeaBird's Salvage operations include Detecting & Locating ship lifting, clearing ports/canals/jetties of wrecks & explosives. SeaBird has extensive experience in Offshore oil fields Maintenance & Repair projects such as Anodes retrofitting and Mechanical repair works, etc. SeaBird's Onshore support bases provide Essential Logistic & Technical support for the Offshore Activities. This includes a Private communication network of Telephone , Wireless and Data Transfer system. Also it includes Spare Parts Warehouses, Supply stores, Repair yards, Accommodation & Messing facilities for crews, etc. SeaBird is a FREE ZONE Joint Stock Company; its official headquarters are located in Port Said, with offices in Cairo, Alexandria and Abu Dhabi New Page 1 Welcome Marine Diving Survey Salvage Projects Fleet BASES Operation Port EL TOR The SeaBird fleet embraces a wide range of specialized tonnage able to perform any exploration/production related support duties. The fleet includes Anchor Handling, Tug Supply vessels, Survey ships and crane/Flat top Barges. Our vessels are equipped with Fire Fighting capabilities and fitted with oil pollution detection and control systems SeaBird owns and operates 29 Vessels and it is the largest Egyptian Company in this field . Our fleet consists of : 15 Anchor Handling Tug Supply Vessels. 10 Purpose designed Tug/Mooring, Survey, Diving-Support Boats with Fire Fighting facilities. 2 Crane/Deck Barge. 5 Anchor Handling Tug/Supply Vessels - owned by "MZ" - manned operated and managed by SeaBird. "MZ" is a joint venture owned by SeaBird and TIDEWATER MARINE CO. 3 Mooring and Supply Vessels owned by Gulf of Suez Oil Co. (GUPCO), manned and operated by SeaBird. 6 Tug and anchor handling & supply boats owned by Sumed and manned and operated by SeaBird. 13 Mooring and service boat owned by Sumed and manned and operated by SeaBird. Vessels are operated and manned by SeaBird's experienced Crews who are thoroughly familiar with all the facets of Oil field Supply, Rig and Barge Tow, Anchor Pattern Handling, Survey operations and Berthing for all types of commercial tonnage. New Page 1 Welcome Marine Diving Survey Salvage Projects Fleet Bases Operation Port EL TOR Since 1978, over than 6000 successful dives are carried out yearly by SeaBird's divers covering all types of under-water services. SeaBird & Oil Services is the largest ship owner and diving company in Egypt. We are involved with all the Companies working in the oil field in the Gulf of Suez and the Mediterranean Sea, offering them marine services and a wide range of under-water diving tasks. SeaBird & Oil Services was formed in 1978. It has grown to reach the standards of the International Diving Companies, using the most updated equipment and supported by experienced management and highly educated supervisors. During the growth of our Company, it has been the SeaBird policy to achieve a high degree of professionalism in our services. We have succeeded in employing Experienced Diving Teams and sending them to the United Kingdom, to get the refresher specialized courses needed. Our qualified divers are experienced in using air and mixed gas, also in diving from D.P. Vessels and capable to perform the following attentive tasks: Non destructive test. Splash zone coating. Anodes retrofitting. Offshore grouting operations. U/W mechanical repair. S.B.M. (Single Buoy Mooring)inspection and maintenance. Under water hot and cold cutting and welding. Semi sub rigs bottom survey. Power cable laying and repair operations. Coring and piling. Marine growth removal using water jetting liqua blaster. Pipelines and risers inspection. Sea berth inspection and maintenance. Rigs coast guard inspection. Construction operations. Video inspection using colored and low light sets and closed circuit systems. Corrosion protection system survey. All the above operations are usually performed under the supervision of most Classification Societies and Registration Offices, (i.e. Lloyds Register of Shipping, American Bureau of Shipping, etc.), engaged in offshore activities. In November 1978, SeaBird carried out its first underwater operation in Alexandria. Four divers using oxy-arc cutting equipment burned a number of 18" square holes in the drainage casing on Wepco platform of Abu Qir. Since that date, SeaBird's divers performed all over the coasts of Egypt in offshore field operations. SeaBird for oil services working in the field of marine and diving services in the middle east , and in salvage , survey , anitpollution , and all other services related to oil industry. , Port El Tor , El Tor , Tor , El-Tor Prot , EL YAM , Red Sea , Egyptian Port , SeaBird COMPANY , largest offshore marine service fleet in Middle East , Middle East , Sinai Introduction: Port El Tor is one of the oldest ports in history and an ancient pharaonic garrison town in South Sinai. El Tor (previously called El Yam and Raithu ) welcomed the Prophet Moses and his followers during the escape, provided them with food and water in their great escape from Pharon. In the second century, the city was an asylum for the Christians who safely settled in the city fleeing the roman tyranny. From this days Port El Tor has its importance & weight among other Red Sea Ports. During the 16-18 centuries Port El Tor was the main Egyptian Port on the Red Sea. During the 19 & 20 centuries Port El Tor was mainly used as a quarantine for Moslem Pilgrims, returning from Mekka. Quarantine Buildings are still existing inside the port. In 2004, SeaBird COMPANY, with its largest offshore marine service fleet in Middle East and long experience in the field or management and operation of specialized ports, signed with the Egyptian government a long term contract for managing and operation of Port El Tor. SeaBird is planning to upgrade the port, increase its facilities & extend the Port capacity to accommodate larger sizes & bigger numbers of vessels. Welcome Marine Diving Survey Salvage Projects Fleet Bases Operation Port EL TOR El Tor Port E-Mail: seabird@seabird-marine.com m COPYRIGHT 2003 SeaBird Group INC. - Computer Department ALL RIGHTS RESERVED. New Page 1 Welcome Marine Diving Survey Salvage Projects Fleet BASES Operation Port EL TOR Due to the fact that our diving teams are EX-NAVAL force staff with great experience in cleaning ports from mines, explosives, and obstacles and salvage activities, our qualified divers are experienced in using air and mixed gas, diving from D.P. Vessels, and capable to perform the following attentive tasks: SALVAGE SeaBird SURVEY DIVISION has the expertise of the highest standard. We own high quality technical equipment to execute Sea bed profiling & Surface/Subsurface surveys, by using the Side scan sonar, trisponders and Sub bottom equipment (magnetometers). This equipment is designed to perform identification, description and locating all kinds of wrecks and any metallic or non metallic objects, either buried or not. All these techniques are always done before executing any salvage operation. Calculation, planning and executing of grounded defective and damaged ships, using all means available on site such as towing, trimming, lightening and tide, etc. SHIP LIFTING Swinging, calculation, planning and executing of sunk ships using: Rubber of solid pontoons up to 200 tons lifting capacity . Floating cranes. Purchases. U/W OXY - Electric and explosives and lighten techniques. The ship lifting operations performed from any practical depths using even Zigzag - Course lifting. CLEARING These operations performed mainly in ports, jetties and canals to recover wrecks and explosives. Diving support for jetty construction works. Submarine cables laying New Page 1 Welcome Marine Diving Survey Salvage Projects Fleet Bases Operation Port EL TOR It is worth mentioning in this regard that SeaBird is considered one of the leading Egyptian companies that undertakes off-shore construction repair works. The following are samples of the projects carried out by SeaBird & OIL SERVICES - Projects Sector: FUJIKURA ROUTE SURVEY JULY 1983 SeaBird carried out a route survey for submarine cables at Abu Qir between platforms P1 & P2. Our final report and maps have been approved and used as main supporting documents to determine the final cable route. WEPCO CABLE LAYING 1983 SeaBird & FUJIKURA jointly completed the laying of 6600 volt cross linked polyethylene insulated composite submarine cables with communication conductor in Abu Qir offshore gas field on schedule. This included: 1. Receiving, transporting and loading of cable and equipment. 2. Route survey, plotting and placing marker buoys. 3. Installation and rigging the cable laying equipment on the cable laying barge, MOS JAMBO I. 4. Fabrication and inspection of riser clamps. 5. Sea trials of cable laying equipment. 6. Fabrication and installion of underwater cable protection. 7. Inspection and video taping of completed subsea cable. The complete installation, inspection and testing continuously monitored by representatives of WEPCO, ENPPI & G.L., were to their satisfaction. SUCO CABLE LAYING 1984 SeaBird completed the laying of 2x11 KV electrical power sub sea cables in SUCO offshore oil field at Ras Budran. The operations included: 1. Receiving and loading of two cables, each 5500 meters. 2. Route survey, plotting marker buoys. 3. Installing and rigging the cable laying equipment on our barge MOS JAMBO I. 4. Laying one cable from shore to the jacket RB-PP-B and another from shore to the flare platform. 5. Cables running parallel to existing pipelines at 5 meters spacing prior to entering J-tube via lazy loop. 6. Inspection and video recording for both cables. 7. Protecting the cables by cast iron clamps at the coral areas and the last 200 meters close to the platform and flare. 8. Sandbagging the suspensions. The complete installation, inspection and testing was continuously monitored by representatives of SUCO & GERMANISCHER LLOYDS. SUMED TEMPORARLY REPAIR OF 32 INCHES SEA LINE 1986 During 1985, our diving team on board tug boats SUMED 4 and SUMED 10 have cut 32" deballast sea line and plugged with plidco flange and blind flange. PETROBEL U/W INSPECTION 1986 Two diving teams were working 24 hours a day to perform a complete inspection on 18 jacket and production platforms. The scope of work was: 1. General Visual inspection 2. U.T. inspection 3. CP Potential readings and anodes inspection. 4. Marine growth removal. 5. Debris survey. 6. Still photos and video recording. 7. Scour Survey. 8. Magnetic particle inspection on nomitated welds. WEPCO U/W INSPECTION 1987 Structure integrity monitoring survey of two 4 legs platforms. Scope of work was as follows: 1. Marine growth measurements. 2. Ultrasonic metal thickness measurements. 3. Potential readings. 4. Magnetic particle inspection on nominated welds. 5. Still photographs and video. 6. A complete report was compiled and submitted on completion to the client's satisfaction. GUPCO SUPPORTING PIPE LINE CROSSINGS NOV. 1987 SeaBird's divers executed an excellent job at Ras Shukeir, using for the first time a D.P.vessel and 30 divers covering 24 Hrs. working time to support all the p/l crossing at the Morgan field by sand/cement bags. Most of the work was at mixed gas depth. GUPCO INSPECTION OF PLATFORM GS 382 1988 SeaBird's divers executed a complete survey for the damaged platform GS 382 after the collision with a Japanese tanker. The inspection was performed underwater and also for the above water partion of the platform, after completion of this job. The diving team executed an inspection for most of the boat landings at GUPCO offshore fields. PETROBEL U/W SURVEY FOR 31 TEMPLATES JAN. 1991 Above and under-water survey for 31 templates and production platforms. Scope of work was as follows: 1. Above and under water M.P.I. test. 2. Above and under water U.T. inspection 3. Marine growth removal 4. Above water inspection and lay out of top side facilities of the production platforms, including structural framing, bridges, weight /C.O.G., supporting beams and spans inspection. 5. Painting and coating for the above water structure. 6. Video and still photo. 7. Scour and debris survey. 8. Wall thickness measurements using graphical techniques (A.Scan) and direct digital reading (Sea Prob.200) All the above mentioned jobs were supervised and witnessed by GERMANISCHER LLOYDS, ENPPI and TECNOMARE representatives. PETROBEL (AGIP) NOV. 1991 Complete inspection and repair for 41 platforms at BELAYIM field. The scope of work was as follows: 1. N. D. T. and video recording 2. Boat landing repair and replacement. 3. Coating for the splash zone area. 4. Mechanical repair for the damaged members (fabrications & Installations) 5. Anodes fabrication and installation. 6. Routing for platforms legs. All the above mentioned jobs are performed and certified by G.L. and ENPPI Classification Societies. GUPCO (AMOCO) OFFSHORE PIPELINES SUPPORTING PR 5/91 Dec. 1991 Installing dura bags & Mattress bags for supporting the crossing and free spans of 24 , 18 and 6 sealines (Task A & B) KUWAIT OIL COMPANY LOCATION: KUWAIT (K.O.C.) AL-TAMEER PROJECT NOV. 1992 to APRIL 1993 The state of KUWAIT's main oil export facility "Sea Island" was severly destroyed during Gulf War and has to resume its function with least delay. Owners, Kuwait Oil Company (KOC) / Bechtel International invited SeaBird among 12 of the worlds major international Offshore construction companies to bid for reconstruction of the Island and Sea Pipe Lines. SeaBird received the tender documents 26/9/92, submitted the offer on 19/10/92, awarded the contract on 16/11/92. Preparing a successful big engaging subcontractors covering almost all offshore activities, was itself not a small achievement. Pipe spools and steel fabrications started the next day of contract award, and diving support vessel SeaBird Explorer deployed from Egypt with divers and UEOD divers to investigate the site and locate and deburry 30 years old laid sea pipe lines. The onshore fabrications were completed, construction and derrick barge, cargo barges together with 6 vessels marine spread were on site on 1/1/93 starting the operation. Mechanical works were completed on 26/3/93 working on 48 inch crude sea pipe lines and 20 inch bunker sea pipe lines for the owners urgency . The project ended by successful hudrotesting 16 miles of each line. Scope of Work Offshore Export Facilities reinstatement, including the following: a) Fabrication Onshore . Fabricate new topsides valves and piping skid. . Fabricate riser support piles and tie backs to jackets. . Fabricate riser protection cage. . Fabricate subsea tie-in spools and spool pieces . Fabricate risers. . Fabricate topside piping and install valves. . Procure any shortage of materials to complete the work. b) Fabrication and Installation Offshore Work Associated with Platform-C J Jumpover Installation . Remove existing topsides equipment from Platform C. . Remove bridge from Platform-C to Platform-D. . Remove boat fenders on East and West side of Platform-C. . Remove access ladders on Platform-C. . Transport and install new topsides valve and piping skid on Platform-C. . Transport and install riser support piles and tie backs to the jacket. . Transport and install riser protection cage. . Transport and install 48" and 20" subsea pipe spools. . Tie-in existing pipelines to new pipeline sections utilising mechanical connectors. . Transport and install risers. . Transport and install topside piping and valves. . Hydrotest pipelines from shore end to SPM. . Procure any shortage of material to complete the work. . Subsea survey. . Procure and install grout mattresses on bends and fittings as per drawings. . Procure and install sand bags to support pipeline spans as per drawings. BUNDOQ OFFSHORE OIL FIELD U.A.E. Our construction barge Regina 250 was engaged with an Offshore job "installation of production well head jacket", Sept 1992. * The a-leg steel jacket 85 ton its deck were loaded from Abu Dhabi on board the construction barge Regina 250 transported to Bundoq oil field. * Four 24 inch. cored - grouted piles were driven . * Steel jacket installed and the top side deck was stabled on the jacket. MINA ABDALLA EXPORT TERMINAL LOCATION: KUWAIT (K.O.C.) NOV. 1992 Scope of work Under water repair for 24" crude oil pipe line. One of Kuwaiti export Sub Sea pipe lines was damaged two miles east wards of Mina Abdalla in water depth of 22 mt. * Construction barge Regina 250 supported by two anchor handling tug supply boats, 70 men construction and diving spreads, completed the job in 30 days. * Work included cutting and removing the damaged part of the pipe line and replacement by hyperbaric welding of two new spools and one pub-spool. AGIBA OIL COMPANY LOCATION ASHRAFY - EGYPT WATER DEPTH 160 FT. JULY - AUG. 93 Assistance in killing WH P1 well. - This job is carried out under supervision of SAIPM emergency task force & in cooperation with wild well control company & oceaneering corp. company. Scope of work: - Securing the B1X life conductor to the structure by chain and binders. - By - passing gas through the X- mass tree. - Burning the 20" & 13" conductor casings. - Cutting the 9.5" & 3.5" conductor casings using subsea hydraulic cutter. - Installing the over shot unit and complete pumping cement after opening the subsea safty value. * This job was fully controlled, monitored to the surface by means of 3CC TV. AGIBA FIELD LOCATION ASHRAFI WATER DEPTH 160 FT. OCT. - DEC. 93 Removal of WHP1 platform - total submerged weight is 900 tons. Unit assigned to this job:- 1- Crane barge 1000 ton 2- A.H.T.S. vessels 3- Accommodation vessel 4- Mixed gas deep diving teams 5- Complete set of underwater cutting spread The structure is devided into 4 sections in order to suit cargo dummy barge capacity. An entinsive calculation is done in order to ensure safe lifting for the rack. GUPCO R.22 - SUBSEA X-MASS TREE MAY 94 Activity : - Installation of R.22 subsea X-mass tree. - Divers would assist in rig positioning. - Divers would assist in all preparing, installing and testing operation involved in X-mass tree installation. SUCO CONTRACT # ENG. 624/94 R/F 11 KV. CABLE INSTALLATION BETWEEN PLATFORMS R/F A TO R/F B. APRIL 94 This project, is performed by our barge MOS JUMBO 1 & 2 work vessels supported by complete diving spread and 12 persons diving team. Scope of work covered during this project is to carry out the following activities:- - Disconnecting and paying out the old cable. - Cleaning cable J tubes. - Anchorage of new cable. - Cable laying between the two platforms. - Testing of cable after laying. RANA MECHANICAL CONNECTOR INSTALLATION APRIL 94 Scope of work covered during this project is to carry out the following activities:- - Cold cutting and removing of old PLIDCO Flanges on 6", 12" and 18" pipe lines at Balayim Oil Field. - Installing of two hytech mechanical connectors at each pipe line. - Accurate measurements (length and angle) to be taken between two mechanial connector flanges at each pipe line. - Fabrication of spool pieces for each pipe line. - Supporting spools and mechanical connectors by means of sand bags. GUPCO (AMOCO) MARCH & JUNE 1994 - Splash Zone Coating for M1 & M18 P/L. - Mechanical repair for sea line. WEPCO ATMOSPHERIC PAINTING MAY 1991 - SEPT. 1994 During this project, SeaBird had completed painting of Platforms P2&Q (over 25000 mt2) & NAF Platform (over 6000 mt2), and platform P1 (about 15000 mt2). The scope of work including surface preparation and painting application for the followings 1- All platforms main structures. 2- Machinary (desiel engines, compressors, pumps......etc.) 3. Potable water tanks inside & outside. 4. Fuel tank, pipes values......etc. Appling about 15 paint systems of Hempel paints SUCO RAS BUDRAN - EGYPT JUNE 1994 U/W inspection for Ras Budran platforms. Scope of Work covered during this job was as follows: 1- Above & under visual inspection for all platforms. 2- Test for nominated nodes at each plaform. 3- Marine growth measurements. 4- Video & still photos. 5- Scour and debris survey. 6- Wall thickness measurements for all jacket structures, risers and conductors using direct digital reading set (sea prob 200). 7- Anode inspection for all platforms. 8- Potential measurements at all anodes and at all under water horizontal frames for each platform. 9- Cutting two windows at pump casing of platform RBA & platform RBC. This job was performed by our support vessel SeaBird VIII and 12 persons diving team equipped by complete diving spread & inspection equipment. GUPCO (AMOCO) 1995 - Mechanical repair for 3 risers at BADRI A P/L. - Pipeline repair for 8 P/L installation of misalignment mechanical connector. - Riser repair for 18 riser at M-1 P/F installation of smart flange connection. KUWAIT OIL COMPANY (K.O.C) REPAIR OF DAMAGED SINGLE POINT MOORING AT MINA AL- AHMADI OFFSHORE KUWAIT BY SeaBird & OIL SERVICES (S.A.E) KOC Single Point Mooring (SPM) is Kuwait s main Oil Loading Terminal designed to accommodate a range of Oil Tankers up to 500,000 Tons. The SPM installation includes a fixed Tower and two main structures, Outer Ring and Medium Ring, supported by the Tower by means of Shock Absorber Assemblies to resist, with the appropriate factors of safety, the combined forces of a berthing Tanker s own dead weight, together with all other imposed forces. The SPM was involved in an accident in October, 1993 and sustained serious damages. KOC awarded this Project to MOS in November, 1994. The Scope of Work was as follows : 1. Procurement of Material, except the new Shock Absorber Blocks provided free of charge by KOC, Construction Engineering, Fabrication and Offshore Repair Works. 2. The Repair of six (6) sandwich / shock absorber units comprising the whole outer sandwich system (114 No. blocks with each block made of 4 No. sandwiches), including the complete replacement of the existing shock absorber blocks with the new blocks. 3. Repair of replacement, painting as necessary in full or part of damaged tubular bracing at the inner and outer structure, together with the repair and replacement of any other effected structural members. The Repair Procedure involved : 1. Lifting of the Outer Ring (600 Ton). 2. Lowering of the Outer Ring on pre-installed vertical stanchions. 3. Restraining lateral movement of the Outer Ring by means of radial supports. 4. Recovery and replacement of the Lower Shock Absorber Units. 5. Recovery and replacement of the Upper Shock Absorber Units. 6. Lowering of the Outer Ring on the newly installed Shock Absorber Assemblies. 7. Replacement of inner and Outer Retaining Cable Systems. The Repair works were successfully completed to the full satisfaction of KOC on March 31st, 1995, well within the Contract Period. On March 31st, 1995 KOC re-connected the Floating Hoses to the SPM Loading Arm and a 500,000 Ton Oil Tanker was berthed on April 1st, 1995 for loading of Crude Oil. QGPC BUL HANINE FIELD - QATAR SEPT. 1995 The contract BH-19 Wreckage Removal at Bul Hanine Field Scope of Work covered during this job was as follows :- 1- Cutting the pile of leg A3 at the sea bed level & the end of the jacket s leg. 2- Excavation around leg A1 & cutting it s pile. 3- Cutting the tripod & the side davit of wreck BH-19. 4- Excavation around the conductor at leg B2. 5- Installing the cold cut machine around leg B2 to cut the conductor casings. 6- Connecting six slings to the wreck BH-19 for lifting operation as one lift. 7- Lifting the wreck BH-19 by using the crane of Regina 250 to the deck of the barge. 8- Lifting the tripod, side davit and all scaffolding pipes from sea bed. 9- Video recording during all operations steps. This job was performed by crane barge REGINA 250, tug boat mestar Jackson and 23 persons diving team equipped by complete two diving spread. MAERSK OIL COMPANY SBM INSTALLATION SHAHEEN FIELD QATAR OCTOBER 1995 Scope of Work Scope of Work of this job is as follows:- 1. Diving of 6 piles (water depth 62mt). 2. Connect chains between piles & S.B.M. 3. Under buoy hoses assembly. 4. Floating hoses assembly. The job started on 15 October 1995 by our construction barge REGINA 250, tug boat Mestar Jackson and 16 persons diving team equiped by two complete diving spread and ended on 11 November 1995. GUPCO SURVEY & REPAIR OF OFFSHORE STRUCTURE & PIPELINE CONTRACT PR 15/95 APRIL 1996 Scope of Work Scope of Work covered during this contract was as follows :- 1. Install and repair of boat landing at Morgan-36 Booster Platform. 2. Repair 18 oil between Morgan-36 to Morgan-8 in two location using hydrotech SPRU Mechanical connector & oceaneering smart flange connectors. 3. Repair & support M-45 pipeline. 4. Install underwater clamps for the additional slots at Badri C & October G Platforms. 5. Install and repair of boat landing at S-B 305 Platform. 6. Repair the 8 high pressure gas line from R-6 to SB 305 using hydrotech connectors (PEC). GUPCO ERDMA 1 - SUBSEA X-MASS TREE MAY 1996 Activity : - Installation of Erdma 1 subsea X-mass tree. - Divers would assist in rig positioning. - Divers would assist in all preparing installing and testing operation involved in X-mass tree installation. GUPCO JULLY-8 PLATFORMS NOV. 1996 - Installation of 40 anodes (C.P. reading before & after anodes installation) - Flooded member inspection. - Cement grouting for platforms legs (annuals & elephant bags). AGIBA 16 P/L DAMAGED SECTION REPAIRS MAY - JUNE 1997 Under water connection using hot tap and stopple plugging systems without shut down of production. The project included :- - Removing the weight and dope coating of the 16 P/L at Hydrotap fitting locations & supporting the pipeline by sand / cement bags. - Installing two 10 /16 hydrotap fittings on the 16 P/L. - Installing two 16 /16 stopple fittings on the 16 P/L. - Hot tapping operation. - Installing and supporting 10 by pass by sand/cement bags. - Plugging and flushing the damaged section of the 16 P/L. - Cold cut the damaged section of the 16 P/L. - Installing two pipe end connectors. - Installing the new 16 spool piece. - Installing the 10 , 16 L.O.R. and blind flanges. - Covering the repaired section of the 16 P/L by using grouted mattresses. KUWAIT OIL COMPANY (K.O.C) STATE OF KUWAIT CONT. # 97 G047 OCTOBER 1997 Underwater Survey & Structural Integrity Analysis for Sea Island Dolphins A, B & C. MPI inspection, coating inspection, general & close visual inspection, wall thickness measurement, still photographs & video recording. The integrity analysis done by Lloyds Register. ADMA - OPCO UNITED ARAB EMIRATES ANODE REPLACEMENT COMPAIGN 1997 CONT. # 6269 OCT. 1997 - Diving Team on board M/V Safiya during the contract of 1997. Anode replacement campaign for subsea pipelines and wellhead towers in both Zakum and Umm Shaif fields, carried out the following activities :- * Mark the field joint (K.P.) of the pipeline. * Cleaning the closed field joint by using liqua blaster M/C. * Install block anode (35, 45, 60) kg anodes. * Install bar anodes 308 Kg at wellhead towers. * Remove the mechanical anchors, remove the old anode, weld new 10 kg block anode and re-install the mechanical anchor. * C.P. reading and still photos for the anodes after installation. GUPCO WELL GS # 373-2 SUBSEA SERVICES MARCH 1998 Saturation diving operation using our Sat. System on board MD 300 barge. The scope of work is to repair the subsea well head including an entire procedure, locate the rig over the well head, re-establish all the disconnected pipe and hoses. TEXACO KUWAIT WET WELDING AUG. SEPT. 1998 Wet welding of 36 subsea pipeline end manifold supports at birth No.2 at Mina Saud Terminal including wet welding procedure specification, procedure qualification record and welder qualification according to American welding society D3.6 1993 code (specification for under water welding Class B) Weld visual inspection and M.P.I. for 100% of the welds ABU DHABI MARINE OPERATING COMPANY (ADMA-OPCO) S.B.M. CHANGE OUT OCT. NOV. 1998 Replacement of mooring chains on tanker berth #3 at Das Island, carried out the following activities :- 1. Pre-construction survey. 2. Disconnect subsea hoses & blind under buoy flanges. 3. Disconnect all 6 chains from buoy & lower to seabed. 4. Recover chains # 1, 3, 4, 6 at buoy end disconnect clamp weights and dredging around pile of chains # 1, 3, 4, 6 to burning the old chackles of the chains. 5. Connect the new chains to the piles # 1, 3, 4, 6. 6. Connect the new chains to the clamp weights. 7. Connect chains to buoy & adjust chain angles. 8. Install subsea hoses to the buoy. 9. As-built survey. New Page 1 Welcome Marine Diving Survey Salvage Projects Fleet Bases Operation Port EL TOR Anchor Handling Tug Supply Vessels Name Main Engine Remarks SeaBird III 1900 BHP SeaBird IV 2740 BHP SeaBird V 3000 BHP SeaBird VI 3000 BHP SeaBird VII 4200 BHP SeaBird VIII 4200 BHP SeaBird IX 4200 BHP Fire Fighting SeaBird X 4200 BHP Fire Fighting SeaBird XI 4200 BHP Fire Fighting SeaBird XIII 4600 BHP Fire Fighting SeaBird 55 3000 BHP SeaBird 85 6000 BHP SeaBird 86 6120 BHP D.P SeaBird 87 6120 BHP D.P SeaBird 94 4340 BHP SeaBird 95 4340 BHP Diving Support , Survey Vessels Name Main Engine Remarks SeaBird Explorer 3000 BHP Crane / Deck Barges Name Dead Weight Remarks MOS Jambo1 1500 Ton 25 Ton Crane SeaBird 300 2228 Ton Main Crane With Boom Length 170 ft , 110 Ton At 12.19 meter , 10.48 Ton At 48.77 meter Material Barge 201 1000 Ton Length 36 , bread 16 Height 3.5 meter Mooring / Light Towage And general Services Boats Name Main Engine Remarks MOS I 150 BHP MOS II 284 BHP Pedestal Crane General Purpose Tug / Mooring Boats Name Main Engine Remarks MOS VII 979 BHP Pedestal Crane MOS VIII 979 BHP Pedestal Crane MOS IX 500 BHP Pedestal Crane MOS X 500 BHP Pedestal Crane General Purpose Mooring Boats Name Main Engine Remarks MOS V 480 BHP Pedestal Crane MOS VI 480 BHP Pedestal Crane Diving Support , Mooring , Light Towage And General Service Boats Name Main Engine Remarks MOS III 284 BHP Pedestal Crane MOS IV 284 BHP Pedestal Crane New Page 1 Welcome Marine Diving Survey Salvage Projects Fleet Bases Operation Port EL TOR To ensure the reliability and seaworthiness of SeaBird's fleet at all times, and to render them capable for exploration operations; to ascertain their management and their maintenance, SeaBird has established back-up stations and support bases on the shores of the Mediterranean and the Gulf of Suez. SeaBird's Onshore Stations are based at: ALEXANDRIA PORT SAID ABU DHABI ABU RUDIES RAS SHUKIER RAS GHARIB Prot EL TOR All SeaBird's onshore bases, our Main Office, and our Branch Offices are connected through a network of telephone and wireless communication system. In addition to the above a wireless communication system is available connecting all bases and offices with our Fleet units that are currently maneuvering in the Mediterranean and Gulf of Suez. SeaBird's Onshore Bases can furnish and provide a range of facilities, such as the following: 1. Spare parts warehouses: in addition to the standard spare parts found on board of every vessel, there is a second line of inventory spares and replacement parts available in SeaBird's onshore bases located in Alexandria and Abu Rudies. 2. Providing additional Crew and/or personnel as the case may be and as required for the operational requirements. 3. Providing all consumables, supplies, deck and engine stores fuel and fresh water required running the operations. 4. Providing repair facilities, such as the following: All main and auxiliary engines temporary repairs. Stern Gear temporary repairs. Replacement of defected machinery and parts on board. Welding and Cutting. Machining of Machine elements and parts needed for repairs. Underwater inspection and Diving support for underwater repairs that may be needed. Electric and Electronic workshop for the electronic equipment that may need maintenance. 5. Providing Messing and Accommodation for personnel and crew members whenever needed. New Page 1 Welcome Marine Diving Survey Salvage Projects Fleet Bases Operation Port EL TOR In addition to the services provided by 24 Marine Units owned by SeaBird, SeaBird is also managing and operating other MARINE UNITS owned by other Companies. The services rendered in relation to this type of activity include Crewing, Manning, Operating, Maintaining, Navigating and Managing the vessels. Also, in January 1993, SeaBird & OIL SERVICES was awarded the contract to manage the Arab Petroleum Company "SUMED" pipeline to perform the required activities for mooring services and maintenance of all floating units. These include: 3 Units Anchor Handling Supply 3 Heavy Weather Tug Boats 13 Service and Mooring Boats Plus, two Slipways and 2 Workshops for immediate repairs, in order to ensure efficient operation at Sumed terminals. The Function of the Two Terminals is as Follows: Ain Sukhna Terminal: The Ain Sukhna off-shore terminal receives tankers to unload crude oil via four (SPM(s); two of which are capable of accommodating fully loaded vessels up to 350,000 DWT, one capable of accommodating fully loaded vessels up to 500,000 DWT and the fourth capable of accommodating fully loaded vessels up to 185,000 DWT. Of the 4 SPM(s), two are connected to a sealine 48" N.D. and approx. 5.0 km long and one is connected to a sealine 52" N.D. and approx. 7.5 km long, whereas the small SPM is connected to a sealine 42" N.D. and approx. 3.0 km long. Each SPM is equipped with hawsers, pick-up ropes, floating and underwater hose strings (details of SPM facilities are given in the technical specifications). Moreover, a laid-up SPM is stored at Sukhna boat harbour. The off-shore facilities include one water intake sealine 48" N.D. and one 20" N.D. effluent sealine of approx. 700 meters and 400 meters long respectively. Sidi Kerir Terminal: The Sidi Kerir off-shore terminal receives tankers to load crude oil via six SPM(s), three of which are capable of accommodating fully loaded vessels up to 350,000 DWT, whereas the other three are capable of accommodating fully loaded vessels up to 150,000 DWT. Each of the big SPM(s) is connected to a sealine 48" N.D. and approx. 8.0 km long, whereas each of the small SPM(s) is connected to a sealine 42" N.D. and approx. 5.0 km long. Each SPM is equipped with hawsers, pick-up ropes, floating and underwater hose strings (details of SPM facilities are given in the technical specifications). Moreover, a laid-up SPM is stored in French Harbor about 30 km east of the terminal or at Sidi Kerir boat harbor. All SPM(s) are equipped with all facilities for simultaneous loading of crude oil and unloading of dirty ballast via a separate floating and underwater hose strings and three sealine, as follows: Two 32" N.B. and approx. 8.0 km long, connected to one big SPM and one small SPM. One 32" N.D. and approx. 5.0 km long, connected to the fifth small SPM. The off-shore facilities include a water intake sealine 48" N.D. of about 700 meters long. New Page 1 Welcome Marine Diving Survey Salvage Projects Fleet BASES Operation Port EL TOR Site Surveys of Drilling locations and pipelines routes surveys form an essential part of SeaBird's total support functions. Bathymetric, Morphologic, Geoseismic, Geotechnical equipment are all available including a Vibro and Gravity Corers to establish Bottom stability for Jack Ups or Holding Quality for Semi-Submersibles Anchors in accordance with the designed parameters and the requirements of the Major Classification Societies and registration offices, (i.e. Lloyds Register of Shipping, American Bureau of Shipping, etc.), Offshore / Onshore lab tests with results and engineering recommendations are submitted in preliminary / final reports complete with charts as per clients' requirements. This activity is technically backed-up by the vast experimental and practical technology of two reputable international companies; RACAL SURVEY LIMITED UK. & FUGRO - Mc CLELLAND ENGINEERS B.V. NETHERLANDS New Page 1 Welcome Marine Diving Survey Salvage Projects Fleet Bases Operation Port EL TOR Chairman Office Marine Sector Diving Sector Projects Sector Operations Sector Administration Financial Sector Engineering Sector Computer Dept. Cairo Office PortSaid Office Communication dept. El-Tor Port Abu Dhabi Office Cairo Alexandria Port Said GULF Region 33 , Gol Gamal St , Dokki , Mohandessin , 12411. Tel : 302 2993 346 1149 Tlx : 21447 CAMOS UN Fax : 346 3380 10 Ahmed Yehia St. Gleem , 21411 Tel :5852899 Tlx : 54497 MOS UN Fax : 5834668 16 El Gomhuria St . , 42311 Tel : 221 771 334 134 335 134 Tlx : 63271 MARIDIV UN Fax : 236 436 Abu Dhabi P.O Box : 44992 Tel : 742 074 Fax : 743 997 SeaBird for oil services working in the field of marine and diving services in the middle east , and in salvage , survey , anitpollution , and all other services related to oil industry. , Port El Tor , El Tor , Tor , El-Tor Prot , EL YAM , Red Sea , Egyptian Port , SeaBird COMPANY , largest offshore marine service fleet in Middle East , Middle East , Sinai Anchor handling , Tug Supply vessels , Marine Construction , Fire Fighting , Antipollution ....... SeaBird was founded in 1978 with the aim of meeting Egypt's requirements of MARINE AND OFFSHORE services with the Egyptian Calibers, the thing that was lacking in the Egyptian market. Since then, the range of the most integrated, prompt package of MARINE AND OFFSHORE services offered by SeaBird, has steadily increased to become one of the most sophisticated range a competitor can afford. Thus, SeaBird, has chosen to invest heavily in new specializes in Marine Offshore Work such as Marine activities, Diving Activities, Salvage, Offshore Oil Fields Maintenance & Repair Projects, Owns & Maintains Onshore Support Bases. SeaBird owns & maintains a Support Fleet. New Page 1 Welcome Marine Diving Survey Salvage Projects Fleet Bases Operation Port EL TOR To ensure the reliability and seaworthiness of SeaBird's fleet at all times, and to render them capable for exploration operations; to ascertain their management and their maintenance, SeaBird has established back-up stations and support bases on the shores of the Mediterranean and the Gulf of Suez. SeaBird's Onshore Stations are based at: ALEXANDRIA PORT SAID ABU DHABI ABU RUDIES RAS SHUKIER RAS GHARIB Prot EL TOR All SeaBird's onshore bases, our Main Office, and our Branch Offices are connected through a network of telephone and wireless communication system. In addition to the above a wireless communication system is available connecting all bases and offices with our Fleet units that are currently maneuvering in the Mediterranean and Gulf of Suez. SeaBird's Onshore Bases can furnish and provide a range of facilities, such as the following: 1. Spare parts warehouses: in addition to the standard spare parts found on board of every vessel, there is a second line of inventory spares and replacement parts available in SeaBird's onshore bases located in Alexandria and Abu Rudies. 2. Providing additional Crew and/or personnel as the case may be and as required for the operational requirements. 3. Providing all consumables, supplies, deck and engine stores fuel and fresh water required running the operations. 4. Providing repair facilities, such as the following: All main and auxiliary engines temporary repairs. Stern Gear temporary repairs. Replacement of defected machinery and parts on board. Welding and Cutting. Machining of Machine elements and parts needed for repairs. Underwater inspection and Diving support for underwater repairs that may be needed. Electric and Electronic workshop for the electronic equipment that may need maintenance. 5. Providing Messing and Accommodation for personnel and crew members whenever needed. SeaBird for oil services working in the field of marine and diving services in the middle east , and in salvage , survey , anitpollution , and all other services related to oil industry. , Port El Tor , El Tor , Tor , El-Tor Prot , EL YAM , Red Sea , Egyptian Port , SeaBird COMPANY , largest offshore marine service fleet in Middle East , Middle East , Sinai Introduction: Port El Tor is one of the oldest ports in history and an ancient pharaonic garrison town in South Sinai. El Tor (previously called El Yam and Raithu ) welcomed the Prophet Moses and his followers during the escape, provided them with food and water in their great escape from Pharon. In the second century, the city was an asylum for the Christians who safely settled in the city fleeing the roman tyranny. From this days Port El Tor has its importance & weight among other Red Sea Ports. During the 16-18 centuries Port El Tor was the main Egyptian Port on the Red Sea. During the 19 & 20 centuries Port El Tor was mainly used as a quarantine for Moslem Pilgrims, returning from Mekka. Quarantine Buildings are still existing inside the port. In 2004, SeaBird COMPANY, with its largest offshore marine service fleet in Middle East and long experience in the field or management and operation of specialized ports, signed with the Egyptian government a long term contract for managing and operation of Port El Tor. SeaBird is planning to upgrade the port, increase its facilities & extend the Port capacity to accommodate larger sizes & bigger numbers of vessels. Welcome Marine Diving Survey Salvage Projects Fleet Bases Operation Port EL TOR El Tor Port E-Mail: seabird@seabird-marine.com COPYRIGHT 2003 SeaBird Group INC. - Computer Department ALL RIGHTS RESERVED. New Page 1 Welcome Marine Diving Survey Salvage Projects Fleet BASES Operation Port EL TOR Site Surveys of Drilling locations and pipelines routes surveys form an essential part of SeaBird's total support functions. Bathymetric, Morphologic, Geoseismic, Geotechnical equipment are all available including a Vibro and Gravity Corers to establish Bottom stability for Jack Ups or Holding Quality for Semi-Submersibles Anchors in accordance with the designed parameters and the requirements of the Major Classification Societies and registration offices, (i.e. Lloyds Register of Shipping, American Bureau of Shipping, etc.), Offshore / Onshore lab tests with results and engineering recommendations are submitted in preliminary / final reports complete with charts as per clients' requirements. This activity is technically backed-up by the vast experimental and practical technology of two reputable international companies; RACAL SURVEY LIMITED UK. & FUGRO - Mc CLELLAND ENGINEERS B.V. NETHERLANDS SeaBird for oil services working in the field of marine and diving services in the middle east , and in salvage , survey , anitpollution , and all other services related to oil industry. , Port El Tor , El Tor , Tor , El-Tor Prot , EL YAM , Red Sea , Egyptian Port , SeaBird COMPANY , largest offshore marine service fleet in Middle East , Middle East , Sinai Introduction: Port El Tor is one of the oldest ports in history and an ancient pharaonic garrison town in South Sinai. El Tor (previously called El Yam and Raithu ) welcomed the Prophet Moses and his followers during the escape, provided them with food and water in their great escape from Pharon. In the second century, the city was an asylum for the Christians who safely settled in the city fleeing the roman tyranny. From this days Port El Tor has its importance & weight among other Red Sea Ports. During the 16-18 centuries Port El Tor was the main Egyptian Port on the Red Sea. During the 19 & 20 centuries Port El Tor was mainly used as a quarantine for Moslem Pilgrims, returning from Mekka. Quarantine Buildings are still existing inside the port. In 2004, SeaBird COMPANY, with its largest offshore marine service fleet in Middle East and long experience in the field or management and operation of specialized ports, signed with the Egyptian government a long term contract for managing and operation of Port El Tor. SeaBird is planning to upgrade the port, increase its facilities & extend the Port capacity to accommodate larger sizes & bigger numbers of vessels. Welcome Marine Diving Survey Salvage Projects Fleet Bases Operation Port EL TOR El Tor Port COPYRIGHT 2003 SeaBird Group INC. - Computer Department ALL RIGHTS RESERVED. SeaBird for oil services working in the field of marine and diving services in the middle east , and in salvage , survey , anitpollution , and all other services related to oil industry. , Port El Tor , El Tor , Tor , El-Tor Prot , EL YAM , Red Sea , Egyptian Port , SeaBird COMPANY , largest offshore marine service fleet in Middle East , Middle East , Sinai Introduction: Port El Tor is one of the oldest ports in history and an ancient pharaonic garrison town in South Sinai. El Tor (previously called El Yam and Raithu ) welcomed the Prophet Moses and his followers during the escape, provided them with food and water in their great escape from Pharon. In the second century, the city was an asylum for the Christians who safely settled in the city fleeing the roman tyranny. From this days Port El Tor has its importance & weight among other Red Sea Ports. During the 16-18 centuries Port El Tor was the main Egyptian Port on the Red Sea. During the 19 & 20 centuries Port El Tor was mainly used as a quarantine for Moslem Pilgrims, returning from Mekka. Quarantine Buildings are still existing inside the port. In 2004, SeaBird COMPANY, with its largest offshore marine service fleet in Middle East and long experience in the field or management and operation of specialized ports, signed with the Egyptian government a long term contract for managing and operation of Port El Tor. SeaBird is planning to upgrade the port, increase its facilities & extend the Port capacity to accommodate larger sizes & bigger numbers of vessels. Welcome Marine Diving Survey Salvage Projects Fleet Bases Operation Port EL TOR El Tor Port E-Mail: torport@mosalex.com COPYRIGHT 2003 SeaBird Group INC. - Computer Department ALL RIGHTS RESERVED. New Page 1 Welcome Marine Diving Survey Salvage Projects Fleet BASES Operation Port EL TOR SeaBird was founded in 1978 with the aim of meeting Egypt's requirements of MARINE AND OFFSHORE services with the Egyptian Calibers, the thing that was lacking in the Egyptian market. Since then, the range of the most integrated, prompt package of MARINE AND OFFSHORE services offered by SeaBird, has steadily increased to become one of the most sophisticated range a competitor can afford. Thus, SeaBird, has chosen to invest heavily in new specializes in Marine Offshore Work such as Marine activities, Diving Activities, Salvage, Offshore Oil Fields Maintenance & Repair Projects, Owns & Maintains Onshore Support Bases. SeaBird owns & maintains a Support Fleet. SeaBird is now based in Egypt, having started its activities in 1978. It is well capitalized, with fixed assets close to U.S.D. 60 Million. It has a high reputation among the numerous oil companies that used its services for the past fourteen years. SeaBird's fleet of 29 vessels has a wide range of special ships able to perform any exploration and production related support. The fleet includes Anchor Handling Tug Supply Vessels, Tug/Mooring Vessels, Survey Ships, Crane/Flat Top Barges, Firefighting Vessels, Vessels fitted with oil pollution control systems and pollution monitoring. SeaBird's diving activities are extensive, with over 6,000 dives per year. For example Non destructive tests, Magnetic particle inspections, Jackup rigs bottom survey, Coring & piling, Pipelines inspections, Cathodic protection system survey, Diving support for jetty construction works, Submarine cables laying, etc. SeaBird's clients' list includes PHILIPS, AGIP, AMOCO, BP, SHELL, SANTA FE, TOTAL, FUJIKURA, SAIPEM, K.O.C, GASCO, TEXACO, FERTIL, ADMA-OPCO, VMGL,---etc. SeaBird's Salvage operations include Detecting & Locating ship lifting, clearing ports/canals/jetties of wrecks & explosives. SeaBird has extensive experience in Offshore oil fields Maintenance & Repair projects such as Anodes retrofitting and Mechanical repair works, etc. SeaBird's Onshore support bases provide Essential Logistic & Technical support for the Offshore Activities. This includes a Private communication network of Telephone , Wireless and Data Transfer system. Also it includes Spare Parts Warehouses, Supply stores, Repair yards, Accommodation & Messing facilities for crews, etc. SeaBird is a FREE ZONE Joint Stock Company; its official headquarters are located in Port Said, with offices in Cairo, Alexandria and Abu Dhabi New Page 1 Welcome Marine Diving Survey Salvage Projects Fleet BASES Operation Port EL TOR SeaBird was founded in 1978 with the aim of meeting Egypt's requirements of MARINE AND OFFSHORE services with the Egyptian Calibers, the thing that was lacking in the Egyptian market. Since then, the range of the most integrated, prompt package of MARINE AND OFFSHORE services offered by SeaBird, has steadily increased to become one of the most sophisticated range a competitor can afford. Thus, SeaBird, has chosen to invest heavily in new specializes in Marine Offshore Work such as Marine activities, Diving Activities, Salvage, Offshore Oil Fields Maintenance & Repair Projects, Owns & Maintains Onshore Support Bases. SeaBird owns & maintains a Support Fleet. SeaBird is now based in Egypt, having started its activities in 1978. It is well capitalized, with fixed assets close to U.S.D. 60 Million. It has a high reputation among the numerous oil companies that used its services for the past fourteen years. SeaBird's fleet of 29 vessels has a wide range of special ships able to perform any exploration and production related support. The fleet includes Anchor Handling Tug Supply Vessels, Tug/Mooring Vessels, Survey Ships, Crane/Flat Top Barges, Firefighting Vessels, Vessels fitted with oil pollution control systems and pollution monitoring. SeaBird's diving activities are extensive, with over 6,000 dives per year. For example Non destructive tests, Magnetic particle inspections, Jackup rigs bottom survey, Coring & piling, Pipelines inspections, Cathodic protection system survey, Diving support for jetty construction works, Submarine cables laying, etc. SeaBird's clients' list includes PHILIPS, AGIP, AMOCO, BP, SHELL, SANTA FE, TOTAL, FUJIKURA, SAIPEM, K.O.C, GASCO, TEXACO, FERTIL, ADMA-OPCO, VMGL,---etc. SeaBird's Salvage operations include Detecting & Locating ship lifting, clearing ports/canals/jetties of wrecks & explosives. SeaBird has extensive experience in Offshore oil fields Maintenance & Repair projects such as Anodes retrofitting and Mechanical repair works, etc. SeaBird's Onshore support bases provide Essential Logistic & Technical support for the Offshore Activities. This includes a Private communication network of Telephone , Wireless and Data Transfer system. Also it includes Spare Parts Warehouses, Supply stores, Repair yards, Accommodation & Messing facilities for crews, etc. SeaBird is a FREE ZONE Joint Stock Company; its official headquarters are located in Port Said, with offices in Cairo, Alexandria and Abu Dhabi SeaBird was founded in 1978 with the aim of meeting Egypt's requirements of MARINE AND OFFSHORE services. SeaBird & Oil Services S.A.E